These floaters make sheet steel handling a one-man job — Save up to 50% on labor. Make handling safer. Reduce risk of injury to personnel.

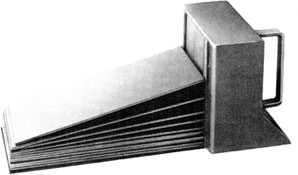

Magnetool floaters separate stacks of painted, enameled, polished, or oily steel sheets one piece at at time, for better handling. They eliminate prying, scratching, marring, and bending of costly stock. Protect expensive dies, punches, shears, and forming equipment.

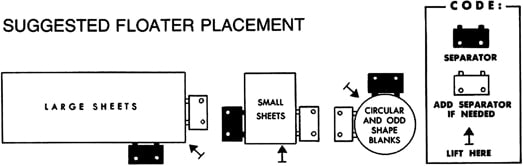

1/8″ thick stainless steel skid bars assure long service by reducing friction drag. Magnets completely enclosed to protect against tampering and dirt. Separator should be 1″ higher than stack of workpieces.

How to use Floater Selection Charts

Chart A: For sheet size (width and thickness) to be handled

NUMERAL shows quantity of Floaters needed — LETTER shows series to use. Chart B shows which floater model in the series to use for planned stack height.

Chart A

Permanent Magnet Sheet Steel Floaters| Stock Width | Thickness | |||||||

| 1/4" | 7 Gage | 8-9 Gage | 10 Gage | 12-14 Gage | 16-18 Gage | 20 Gage | 22-26 Gage | |

| Up to 4" | 1 (H) | 1 (H) | 1 (H) | 2 (G) 1 (H) | 2 (G) | 2 (G) | 2 (C) | 2 (C) |

| 6" | 1 (H) | 1 (H) | 1 (H) | 2 (G) 1 (H) | 1 (G) | 2 (G) | 2 (C) | 2 (C) |

| 12" | 2 (H) | 2 (H) | 1 (H) | 2 (G) 1 (H) | 1 (G) | 1 (G) | 1 (C) | 1 (C) |

| 18" | 4 (H) | 2 (H) | 2 (H) | 1 (H) | 2 (G) | 1 (G) | 2 (C) | 2 (C) |

| 24" | 4 (H) | 2 (H) | 2 (H) | 2 (H) | 2 (G) | 2 (G) | 2 (C) | 2 (C) |

| 36" | 4 (H) | 3 (H) | 2 (H) | 2 (H) | 2 (G) | 2 (G) | 2 (C) | 2 (C) |

| 48" | 4 (H) | 3 (H) | 2 (H) | 2 (H) | 2 (G) | 2 (G) | 2 (C) | 2 (C) |

Chart B

Permanent Magnet Sheet Steel Floaters| Series and Model # | Floater Diameter (inches) | Maximum Stack Height (inches) | ||

| W | D | H | ||

| C-1 | 4-1/4 | 3-1/8 | 4-3/8 | 3-1/2 |

| C-2 | 4-1/4 | 3-1/8 | 7-3/8 | 6-1/2 |

| C-3 | 4-1/4 | 3-1/8 | 10-3/8 | 9-1/2 |

| C-4 | 4-1/4 | 3-1/8 | 13-3/8 | 12-1/2 |

| C-5 | 4-1/4 | 3-1/8 | 16-3/8 | 15-1/2 |

| G-1 | 6-1/4 | 4-5/8 | 6 | 5 |

| G-2 | 6-1/4 | 4-5/8 | 11 | 10 |

| G-3 | 6-1/4 | 4-5/8 | 17 | 16 |

| G-4 | 6-1/4 | 4-5/8 | 21 | 20 |

| G-5 | 6-1/4 | 4-5/8 | 26 | 25 |

| H-1 | 8-1/4 | 5-1/2 | 7 | 6 |

| H-2 | 8-1/4 | 5-1/2 | 13 | 12 |

| H-3 | 8-1/4 | 5-1/2 | 19-1/4 | 18 |

| H-4 | 8-1/4 | 5-1/2 | 25 | 24 |

| H-5 | 8-1/4 | 5-1/2 | 31 | 30 |

Made in USA

Made in USA