The magnetic field of bi-polar magnets have a greater “reach-out” than that of flat-faced electromagnets. For this reason, they perform better than equivalent flat-face magnets when operating through an air gap or any type of non-magnetic material between the workpiece and the magnet. Bi-polars, due to their extended poles, are designed to handle round parts, parts with uneven surfaces, and odd shaped parts. Contoured, auxiliary pole shoes can be added for better contact with the workpiece.

Small Bipolar Electromagnets

12 VDC (24 VDC & 110 VDC Optional)| Model | Width | Length | Height | Mounting | Thread & Length | Location of Leads | Watts | Lbs. Pull | Net Weight | |

| A | B | C | D | E | F | G | ||||

| BP-1407 | 15/16 | 1-5/8 | 1-5/8 | 7/8 | 10-32 X 15/16 | 7/16 | 1/4 | 5 | 25 | 8 oz |

| BP-1406 | 1-11/16 | 2 | 1-13/16 | 7/8 | 10-32 X 15/16 long | 1 | 5/16 | 6.5 | 80 | 1 lb |

| BP-6090 | 1-1/2 | 3-1/2 | 2-5/8 | 2-1/4 | 1/4-20 X 3/8 deep | 3/4 | 5/8 | 12 | 360 | 2 lbs |

| BP-1600 | 2-3/8 | 4-1/8 | 3-7/8 | 2-1/2 | 3/8-16 X 1/2 deep | 1-3/16 | 1-1/8 | 15 | 440 | 6 lbs |

| BP-1602 | 2-7/8 | 5-5/8 | 4 | 3-1/2 | 3/8-16 X 1/2 deep | 1-7/16 | 1-1/8 | 22 | 650 | 11 lbs |

| BP-1601 | 4-1/8 | 7-5/8 | 4-3/4 | 5 | 1/2-13 X 1 deep | 2-1/16 | 1-1/8 | 35 | 1100 | 25 lbs |

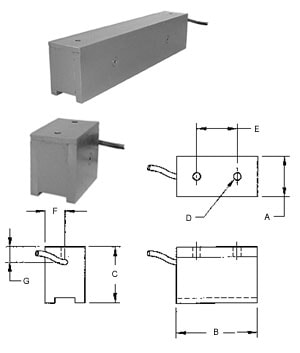

GP Series Bipolar Electromagnets

General Purpose Parallel Pole Design for Various Handling Operations

GP Series BiPolar Electromagnets feature parallel poles which provides an extended field and allows both poles to contact an irregularly shaped part. To provide maximum contact, the poles can be machined or contoured auxiliary pole shoes can be added to provide better contact with the workpiece.

Standard Features:

- (2) Tapped Mounting Holes

- 24″ Leads on 1″ Wide Magnets

- 24″ 18-2 Cord on 2″ Wide Magnets

- Continuous Duty

- 12VDC (Standard), 24VDC and 110 VDC No Charge Optional Voltages

Options:

- Special Pole Shoes

- Special Mounting Hole Location

- Special Cord Lengths

- 120 VAC Versions On Some Models

GP Series Bipolar Electromagnets

| Model | Width A | Length B | Height C | Tap D | E | F | G | Pull Max. | Watts | Weight (lbs) |

| GP-1010 | 1" | 1" | 1-3/8" | 10-32 | 1/2" | 1/2" | 1/2" | 20 lbs. | 4 | 0.4 |

| GP-1020 | 1" | 2" | 1-3/8" | 10-32 | 1" | 1/2" | 1/2" | 80 lbs. | 6 | 0.9 |

| GP-1030 | 1" | 3" | 1-3/8" | 1/4-20 | 2" | 1/2" | 1/2" | 170 lbs. | 11 | 1.2 |

| GP-1040 | 1" | 4" | 1-3/8" | 1/4-20 | 3" | 1/2" | 1/2" | 210 lbs. | 13 | 1.8 |

| GP-1060 | 1" | 6" | 1-3/8" | 1/4-20 | 3" | 1/2" | 1/2" | 260 lbs. | 22 | 2.4 |

| GP-2030 | 2" | 3" | 2-3/4" | 5/16-18 | 2" | 1" | 1/2" | 270 lbs. | 21 | 3.0 |

| GP-2040 | 2" | 4" | 2-3/4" | 5/16-18 | 3" | 1" | 1/2" | 350 lbs. | 22 | 4.0 |

| GP-2060 | 2" | 6" | 2-3/4" | 5/16-18 | 4-1/2" | 1" | 1/2" | 610 lbs. | 38 | 6.0 |

| GP-2080 | 2" | 8" | 2-3/4" | 5/16-18 | 6-1/2" | 1" | 1/2" | 970 lbs. | 52 | 8.0 |

Pull rating is maximum breakaway force on low carbon steel with a cold rolled finish at magnetic saturation.

Made in USA

Made in USA