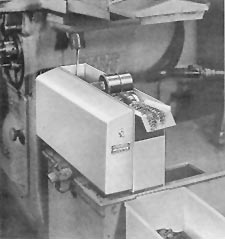

The Magnetool CSID Series Coolant Filter utilizes the indexing drum method of filtration, and is used with water based coolant.

With Coolant Filter switch “ON”, the Magnetic drum remains in a static position. Dirty coolant is fed from the machine into the reservoir of the Coolant Filter and flows under the drum which attracts the ferrous particles and builds up a “cake” of ferrous material. When the coolant passageway is blocked the coolant rises until it touches the probe. (The probe is the 1/4″ diameter stainless steel rod). This activates the motor turning the drum a few degrees, clearing the passageway and allowing the level of coolant to drop and the motor is turned off. The swarf is eventually forced off the end of the discharge chute.

To check the operation of the drum, insert the plug in a 115 Volt line, turn on the toggle switch. Using a steel rod or screwdriver, short the 1/4″ dia. stainless steel probe to the case. The drum will rotate while the probe is shorted to the case.

CSO Series

The CSO Series is used when the coolant is a non-conducting type of oil. The method of magnetic separation is the same as the CSID. However The drum and urethane squeegee roll operate continuously. The oil is squeezed from the swarf and flows back to the drum and eventually to the tank. The swarf is forced off the end of the discharge chute.

CS Series Coolant Filters

| Model | Gallons Per Minute | "A" Magnetic Drum Width | "B" Overall Width | "C" & "D" Height and Length | Net Weight lbs | Motor Data |

| CSO/CSID-30 | 10 | 4-1/4 | 10 | 9-1/4 x 17 | 95 | 120V 60 Hz 1/2 HP |

| CSO/CSID-60 | 20 | 8-7/16 | 13-1/16 | 9-1/4 x 17 | 150 | 120V 60 Hz 1/2 HP |

| CSO/CSID-90 | 30 | 12-5/8 | 17-5/16 | 9-1/4 x 17 | 200 | 120V 60 Hz 1/2 HP |

Made in USA

Made in USA