Magnetic tools use the attractive force between ferrous materials and magnets to accomplish tasks, including holding, stopping, stabilizing, lifting, organizing, and retrieving.

Electromagnets use electricity to generate a magnetic field. A wire coil, usually wrapped around a ferromagnetic core, becomes magnetized when an electric current flows through it. Since electromagnets can be turned on and off, they are considered temporary magnets, only exerting a magnetic force when electricity is flowing. They can be designed in many sizes for both heavy- and light-lifting applications.

Used in construction and manufacturing to lift and sort metal blocks, plates, objects, and steel bars.

Used in automated pick-and-place operations to hold and set up various devices and fixtures.

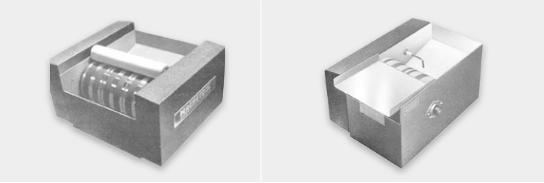

Magnetizers induce magnetism in ferromagnetic materials, such as iron, cobalt, nickel, and certain steels. By aligning the magnetic domains within a material, magnetizers create a unified magnetic field that can transform ordinary metal parts into functional magnets.

For larger magnet materials, Magnetool offers the 50C Magnetizer, which is a more powerful version of the 24C that produces up to 50,000 amp-turns. This unit is ideal for magnetizing larger Ceramic (Ferrite) and Alnico components. Both the 24C and 50C units maintain the same quality construction and reliable performance for which Magnetool equipment is known.

Key features of the 24C magnetizer include:

Demagnetizers are used to reduce or remove a material’s magnetic properties, especially in steel and other ferromagnetic materials. By exposing an object to an alternating magnetic field, the magnetic domain within the material is scrambled, which neutralizes its magnetism. In manufacturing, demagnetizer tools are used to remove residual magnetic properties from steel parts prior to machining, welding, shipping, or cleaning finished parts.

Round loop type demagnetizers are often used in tool rooms or on the shop floor to demagnetize tools and parts without interrupting operations. Items are conveyed through the demagnetizer, which generates a magnetic field and removes any magnetism in the items. When used with production parts, non-magnetic conveyors or chutes are often used to slide the workpieces through the machine opening and into a collection area.

Loop demagnetizers are often used with:

Also known as degaussers, these tools are constructed of heavy-gauge stainless steel cases and available with rectangular openings (up to 18 in. x 36 in.) and round openings (up to 8 in. diameter).

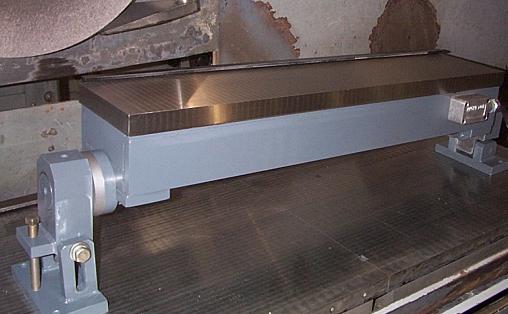

Surface-type demagnetizers can be used to demagnetize metal plates or parts. They are often placed beneath conveyor chutes and belts or operated manually to demagnetize parts in a single layer. The parts must pass over the core area to achieve optimal results.

These demagnetizers are constructed from heavy-gauge, formed steel cases with a top plate and a non-magnetic wear surface. Standard units align with IP40 construction, and custom construction, shapes, and sizes up to IP65 are available.

Electromagnets operate on direct current (DC) voltage, so rectifier controllers are needed to convert the alternating current (AC) to DC. Control options include current and voltage setpoint adjustment.

Chucks and sine plates are precision tools used in metalworking for machining, milling, grinding, and turning. Chucks hold workpieces securely in place, and sine plates use gauge blocks to accurately set angles. They are available in various shapes and sizes and can be used independently or together to meet the needs of any setup.

These highly versatile chucks are available in the following styles:

They utilize ceramic high-power 8V magnets that never require re-magnetizing, and the top plates are constructed of furnace copper, which has been brazed together to create a durable, solid, one-piece structure. These chucks can be used for a wide variety of machining tasks and drilled to specific depths. Removable handles for easier operation and lifting are also available.

The top plates of these chucks can be outfitted with auxiliary plates or machined to accommodate workpieces with complex configurations. They are built to withstand the high torque of grinders, lathes, and other machinery, and provide holding power in a range of different machining tasks.

Parallels are laminated blocks of stainless steel and furnace-brazed steel. They are available in custom shapes and sizes. While they are not magnetic themselves, they are engineered to transfer magnetism from the part being held to the surface of the chucks.

These chucks feature longitudinal (ECL) and transverse (ECT) pole designs for consistent, secure holding power. The poles consist of the following materials, which are brazed together for watertight protection and optimal durability:

Magnetic sine plates are used for precise angular setups and are designed to enable fast, accurate adjustments. They incorporate high-power ceramic magnets to maintain a consistent magnetic force, which keeps the workpiece and tools stable and accurate during operation.

Magnetic filters use strong magnets to capture and remove iron-containing (ferrous) particles and contaminants from liquids.

They improve efficiency in many industrial processes and are used to:

Protect tools and equipment from damage.

Remove ferrous contaminants.

Improve the overall quality of finished products.

Magnetic sweepers can quickly and efficiently remove ferrous metal debris (e.g., screws, bolts, nails) from surfaces where they may be frequently scattered or dropped. They are available in various forms, including handheld magnetic pickup tools, larger sweepers for use with forklifts, and magnetic brooms.

Magnetool also offers repair services for electromagnetic or permanent magnet chucks in our facilities. Services include:

With over 70 years of proven industry experience, Magnetool, Inc. offers a broad range of top-quality, Made in America magnetic tools and products for workholding, handling, lifting, and demagnetizing.

Contact us to discuss your manufacturing process or request a quote today to start your next project.