How Do Electromagnets Work?

Electromagnets are generally made from a piece of iron or steel, also called a core, that is wrapped with a coil of wire, called a solenoid. Electric current creates a magnetic field, and when current flows through the coil, it creates an electromagnet. When the current stops, the magnet is no longer magnetized. For this reason, electromagnets are known as temporary magnets, as opposed to permanent magnets, which generate a magnetic field at all times.

A variable resistor, or rheostat, is used to increase or decrease the power of that electromagnetic field by adjusting the amount of resistive material connected to the electrical circuit. A greater amount of resistance reduces current flow and magnetic field, and less resistance increases current flow and magnetic field.

Types

Magnetool, Inc. uses the basic operating principle behind electromagnetism to make an extensive range of electromagnets suited to different applications. These products include:

- Small flat-faced magnets. These magnets are used to lift or hold flat steel surfaces contacting the face of the magnet. These flat magnets can be used to pick up ferrous materials in automated tasks or to protect safety.

- Small bipolar electromagnets. Also called parallel pole magnets., these have a greater “reach-out” than their small flat-faced counterparts. They provide improved magnetism when non-magnetic material (i.e., air gap) sits between the magnet and the workpiece. Bipolar magnets are used for irregular surfaces and they can be adapted for irregular or round parts with contoured or vee shaped pole shoes.

- Large bipolar electromagnets. With a parallel pole design, these electromagnets improve “reach-out” and allow the north and south magnetic poles to connect with workpieces with irregular surfaces. Bipolar magnets are used for irregular surfaces and they can be adapted for irregular or round parts with contoured or vee shaped pole shoes.

- 120 V.A.C. electromagnets. Our 120v electromagnet products come in rectangular, round, and bipolar options with built-in rectifiers.

- 2 VC bipolar electromagnets. These have an extended, deep, magnetic field for heavy-duty applications, such as horizontal steel-lifting or handling bundles of bars, steel coils, tubing, and pipe.

- Low profile electromagnets. This design is suitable for use with thin materials and reduced-clearance applications.

- “MHE” material handling magnets. These electromagnets are compatible with medium-gauge metal plates and sheets, and can lift a single workpiece off a stack or from a container. Often, multiple magnets are mounted together on a spreader beam for large area sheets and plates.

- Electrically operated permanent magnets. Also called electropermanent magnets, the magnetic field from these specialized permanent magnets can be turned on or off with a short burst of electric current. No electricity is used while the magnet is in the “hold” condition.

- Battery operated lifting magnets. This is a compact and portable electromagnet option. BL magnets have built-in controls and require no external cords. They are a perfect solution for moving materials with fork trucks around the shop or in the yard.

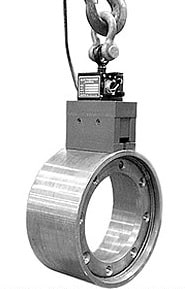

- Round lifting magnets. These disk-shaped magnets are often used for lifting compact solid items like steel plate, billets, and forgings. They can be used singly or in multiples and are available as VDC, operated by existing controls. Optionally, they can incorporate built-in controls with switching for simple hoist use.

- Rectangular lifting magnets. These rectangular magnets can lift numerous plates at a time, along with slabs, castings, forgings, and more. Often, multiple magnets are mounted together on a spreader beam for large area plate lifting.

- BPR Series bipolar lifting magnets. Bipolar magnets have wide-spaced poles, which creates greater “reach out” and a deeper magnetic field. They include a built-in controller with switching that creates a reverse current, which acts as a release function. These magnets use 120 VAC voltage.

The Utility and Benefits of Electromagnets

The ability to turn magnetism on or off is useful for many tasks that require holding, retrieving, moving, or otherwise manipulating a magnetic metal object. For example, an electromagnet can be activated in order to pick up an object and transport it to a new location, then deactivated to put it down or to position and hold an item in a specific orientation.

Electromagnets can also be designed with different coil, pole spacing, and current configurations to create different amounts of force and depth of magnetism for different applications.

Common Industrial Applications

Electromagnets are widely used for many industrial tasks like lifting, moving, holding, and more. Common examples include:

- Magnetic lifting devices for manufacturing, construction sites, and scrapyards.

- Workholding equipment for machining, finishing, and fabrication operations.

Electromagnets From Magnetool, Inc.

Magnetool, Inc. offers a range of electromagnet products for different industrial applications. Our staff can also help you select the right magnetic tool for your requirements.

Contact us today to learn how electromagnets can be used in your application, or request a quote for your next project.

Made in USA

Made in USA